Micromachining

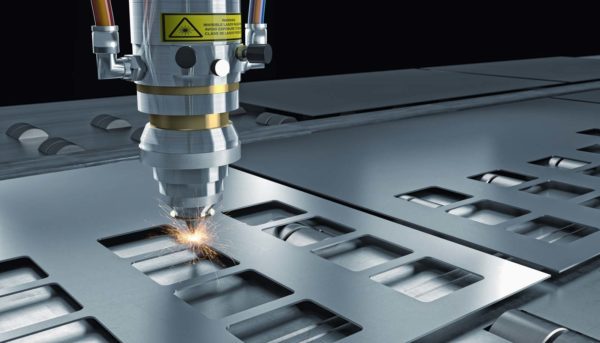

Ultrafast lasers have become the ideal tool for an increased number of applications in the micromachining market. The key benefit is their capability to get high ablation or processing volume combined with remarkable process quality. Most demanding applications rely on the unique properties of ultrashort pulses to be able to remove material without depositing any heat as energy is released faster than thermal effects. This means that each ultrashort pulse can process material with virtually no heat affected zone.

Two pulse regimes can be considered in micromachining depending on the process requirement : picosecond or femtosecond. The choice depends on material to be processed, on ablation rate and process quality as femtosecond pulses tend to offer best quality with a near zero heat affected zone.

SIRIUS and DIADEM are perfect tools for processing high band gap / brittle materials (ceramics, sapphire,…), hard materials mostly with poor thermal properties (glass, Ti, stainless steel,…) with extremely sharp side walls (removing post processing in most cases) and process time much shorter than any other technology can meet.